With a wealth of experience in medical technology and the manufacturing of life-saving devices, Faisal Zain has become a pivotal voice in the conversation around sustainable growth in the pharmaceutical sector. He argues that expanding production to meet global health needs and protecting our planet are not competing priorities but deeply interconnected goals. In our discussion, we explored how innovative facility design can multiply sustainability gains, the transformative role of AI in eliminating waste on the factory floor, and how a commitment to efficient, adaptable manufacturing ultimately builds a more resilient and responsible supply of medicines for patients everywhere.

You mention that growth can be a “sustainability multiplier.” Could you walk us through a real-world example of how a new facility’s design not only expanded production but also achieved specific, measurable environmental gains over older, existing sites?

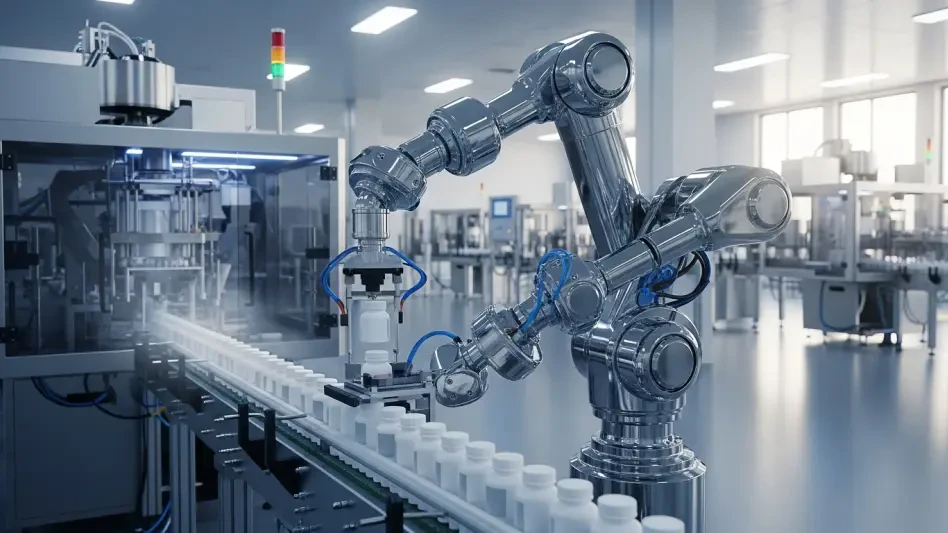

Absolutely. It’s a concept that truly comes to life when you move from theory to concrete and steel. When we approach a new facility, we have a clean slate, an opportunity that’s simply not available with legacy sites. Instead of asking how to fit sustainability into an existing footprint, we ask, “How can this facility meet future demand using the most efficient technology available today?” Imagine an older plant, built decades ago, where energy efficiency was an afterthought. Now, picture a new facility where sustainability is integrated from day one. We’re designing buildings with rooftop solar arrays that power a significant portion of operations, effectively turning the building itself into a source of clean energy. We install smart systems that automate lighting and climate control, ensuring not a single kilowatt is wasted. This design-led approach means the new site can produce significantly more medicine than an older one while using a fraction of the energy and water per unit. That’s the multiplier effect: every increase in capacity simultaneously deepens our positive environmental impact, making our growth a force for good.

The article highlights using AI for “right-first-time” execution. Can you describe how predictive analytics works on the factory floor to prevent waste before it happens? What kind of specific inefficiencies have these tools helped you uncover that were previously unnoticed?

This is where manufacturing feels less like a mechanical process and more like a living, intelligent system. “Right-first-time” execution is about moving from being reactive to being predictive. On the factory floor, machine learning algorithms are constantly analyzing thousands of data points from our production lines—temperature, pressure, viscosity, you name it. These systems learn the subtle patterns that precede an error or a deviation from quality standards. For example, the AI might detect a minuscule vibration in a mixing machine that is imperceptible to a human operator but is a known precursor to an inconsistent batch. It flags the issue before the batch is compromised, saving not only the raw materials but also the energy, water, and time that would have been wasted. Previously, we might have only discovered such an issue during quality control, long after the resources were spent. AI reveals these hidden inefficiencies, the tiny drifts from perfection that, when aggregated, represent significant waste. It’s about catching the whisper of a problem before it becomes a shout.

You emphasize designing multi-purpose facilities. What are the key engineering and regulatory challenges in creating a single site capable of producing a diverse range of medicines, and how does this adaptability translate into quantifiable resource savings over time?

Designing a multi-purpose facility is a fascinating challenge that sits at the intersection of engineering ingenuity and strict regulatory compliance. The primary challenge is preventing any possibility of cross-contamination between different products. This requires incredibly sophisticated air handling systems, modular “ballroom” style production suites that can be easily reconfigured and decontaminated, and closed-loop processes that minimize human interaction with the medicines. From a regulatory standpoint, you have to prove that these systems are foolproof for every single product you intend to manufacture there. It’s a high bar. But the payoff is enormous. Instead of building three separate, specialized factories—each with its own massive carbon footprint, its own demand on the local power grid, and its own land use—we build one hyper-flexible hub. This adaptability means we are conserving immense amounts of resources upfront and ensuring that every square foot of the facility is driving production. Over time, the savings in energy, water, and raw materials are staggering, and it allows us to pivot quickly to produce whichever medicine is most needed, making our supply chain far more agile.

You connect sustainable manufacturing to building a more “reliable, responsible supply of medicines.” Beyond the environmental benefits, how does a facility built on efficiency and renewable energy directly contribute to a more resilient supply chain and better outcomes for patients?

The connection is direct and powerful. Think about what makes a supply chain vulnerable: energy price volatility, grid instability, and production errors that lead to shortages. A facility that generates a large portion of its own power from solar or wind is insulated from those external shocks. It becomes a more stable, predictable node in the supply chain. Furthermore, when you use AI to drive “right-first-time” manufacturing, you drastically reduce the likelihood of a bad batch that could halt production for weeks, leading to a critical drug shortage. For a patient relying on that medicine, a sustainable manufacturing process means their supply is more secure. It’s about building a system so efficient and self-reliant that it can weather disruptions. This isn’t just about being environmentally responsible; it’s about fulfilling our fundamental promise to patients that they will get the medicines they need, when they need them. A reliable supply chain is a cornerstone of patient trust and health.

What is your forecast for the future of sustainable pharmaceutical manufacturing?

My forecast is that sustainability will cease to be a separate initiative and will become the fundamental blueprint for all growth and innovation in our industry. We are rapidly moving past the point where sustainability is a report we publish or a department we fund; it is becoming the core of our operational strategy. In the coming years, I believe you will see a paradigm shift where a company’s ability to manufacture sustainably is directly linked to its license to operate and its long-term profitability. New facilities will be designed to be carbon-neutral from the outset, not as an aspirational goal but as a baseline requirement. The use of AI and data analytics to eliminate waste will become standard practice, and the concept of a circular economy—where water is recycled and materials are repurposed—will be deeply embedded in our processes. Ultimately, the industry will fully embrace the idea that the health of the planet and the health of its people are indivisible. Progress will be measured not just by the medicines we discover, but by how responsibly we deliver them to the world.